With this blog being hosted at and titled after my ham callsign, one might

expect there'd be at least a little radio-related content by this point.

I promise there's some coming, but for a stopgap enjoy this cover shot of a

pamphlet I found buried in the depths of a local antique mall:

I was too overwhelmed with the sensory overload that is shopping at an antique

mall to note down any interesting details, such as the date of publication.

It didn't have a price listed and it seemed like too much trouble to ask, which

is probably good since I really don't need such a volume in my possession.

Still, if there's one interesting takeaway, it's that Sylvania used to make

scopes?

I touched briefly on

Stevenson screens

in my

post on hygrometry,

mostly with regard to how cool it is that their namesake was the father of the

famed author.

I'd never built one myself, and never planned on doing until I get around to

building a full-on weatherstation like I will, uh, one of these days.

Then I realized: my girlfriend has a cheap wireless indoor/outdoor thermometer,

and the remote sensor can be a bit, uh, touchy:

Things like this are why we have 3D printers, so I decided to see what might be

publicly available as far as enclosure designs and run one off real quick.

It turns out, Thingiverse has

many options;

I picked

this one

somewhat arbitrarily.

This was a pretty cool model and brought me a little farther into the mindset

of 3D printing than I've been in the past.

I know there are some pretty radical things you can do once you get there

—

printing individual screw threads or a ball in a cage or an entire planetary

gearset in situ

—

but so far I've always treated it as just another traditional

process, proceding from a drawing and using exact dimensions with known

tolerances etc.

This was a different experience:

since I didn't really have any specific dimensions to match, I just scaled it

with the dumb slider in my slicing software and ran test prints until it was

about the right size to accomodate the sensor.

Also, the height of the whole assembly isn't fixed, instead you can print as

many of the annular section as you want to make it as tall as you want.

I did that until it looked reasonable, drove a self-drilling plastic screw

into the bulkhead to mount the sensor, found some all-thread and acorn nuts to

tie it all together and called it good.

At the end of the day, it was pretty fun building something so

fast-and-(literally-) loose, the sensor works much better, and I think it looks

altogether quite professional hanging there on the back fence.

Every year about this time the weather starts getting interesting,

and every year about this time I kick myself for having forgotten that the

NWS SKYWARN spotter training classes are

only offered in March and April.

Luckily this year I wasn't doing much in April and our local NWS office did a

FABULOUS job of presenting the training courses online, so I finally got my

spotter ID.

It's causing me to pay more attention to the weather and to meteorology as a

science than I have since probably high school.

Aside from some intense thunderstorms this week (including a tornado warning

for cloud rotation observed within city limits, which is VERY uncommon),

it's also been uncharacteristically humid.

Humidity is something we don't often pay much attention to around here, on

account of its often never exceeding 30%.

But I started reading up on the subject and learned a couple interesting things.

An instrument used to measure humidity is called a hygrometer, and they can

be made to work by any of various phenomena.

Mechanical dial-type gauges, such as may be found with a thermometer and

barometer on a wall-mounted weather station, work by measuring the distension

of a material or structure that expands and contracts in response to

atmospheric humidity; human hair is one such material.

The dielectric constant of air changes with humidity, so an electronic gauge

can be made to work by measuring the time constant of a circuit built around an

air-gap capacitor exposed to atmosphere.

Alternatively, solid-state sensors exist which utilize a material whose

resistance or other electrical properties change after absorbing moisture from

the air.

These are found in some consumer devices, as well as in the form of discrete

components which can be purchased and integrated with hobbyist or industrial

systems.

A different, arguably more direct device works on the principle that

evaporation occurs in inverse relationship to air humidity.

Thus, by measuring the temperature differential between the ambient air and an

thermometer evaporatively cooled in presence of same, the air humidity can be

determined.

Such a device is specially called a psychrometer.

These have two thermometers, one "dry bulb" which measures ambient air and one

"wet bulb" which is moistened and reads cooler because of evaporation.

Though I never built one, I remember seeing instructions in many childhood

science books for how to do so.

These were swung around over one's head to create enough airflow to

sufficiently cool the wet bulb; precision instruments use a calibrated fan or

blower to provide a known amount of airflow.

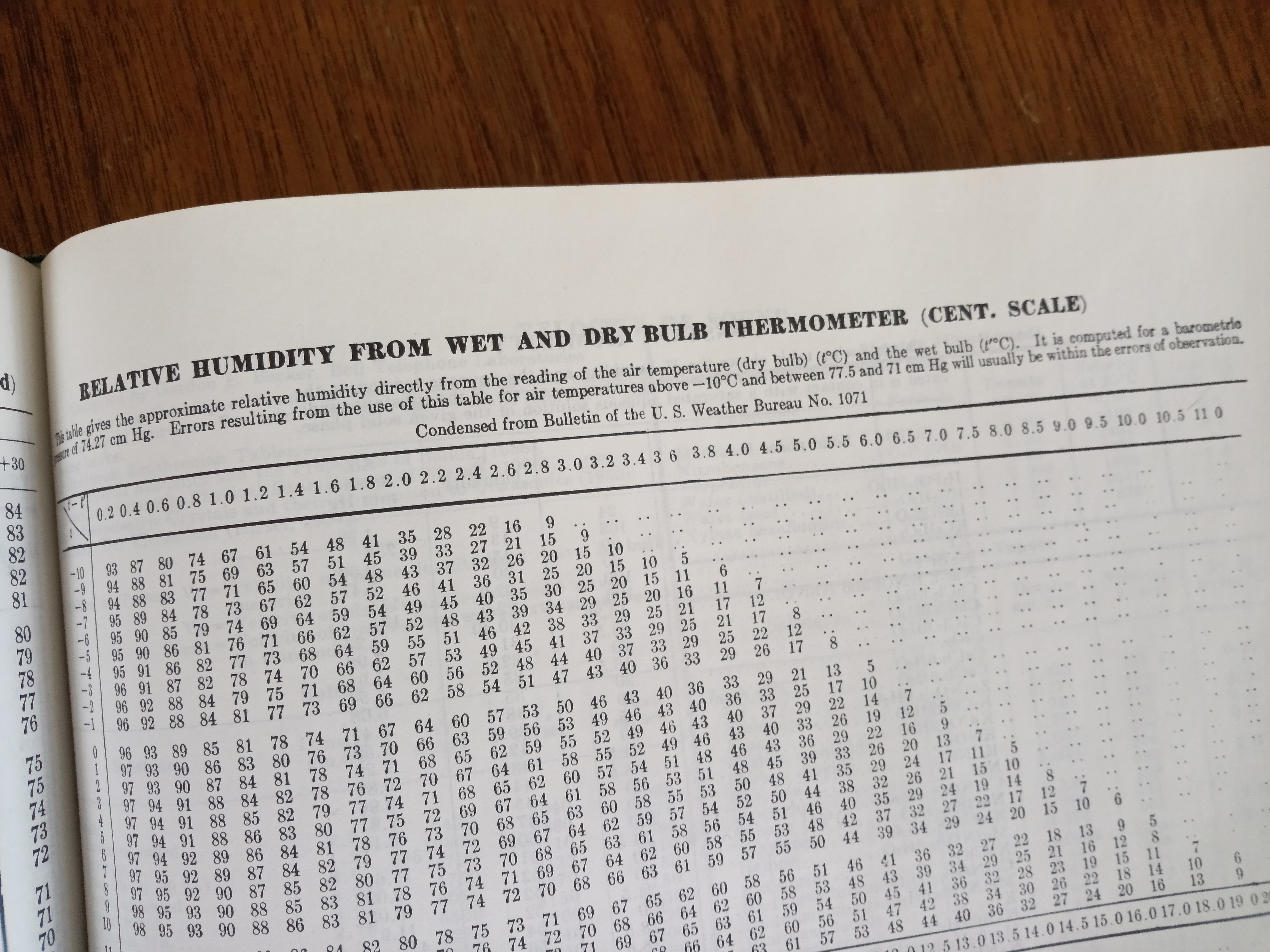

The relationship between humidity and the two temperature readings depends also

on barometric pressure, and, if there's an analytic formula describing this

relationship, I've never seen it.

Instead all I've ever seen are tables, like the one shown below.

In fact, I was given advice by a Physics instructor once to the effect of

"you need a CRC manual from roughly every ten years or so, because they stop

putting certain information in there.

I was trying to find a wet-bulb hygrometer table the other day and I had to

go back YEARS."

Fortunately my 1967 edition has one (alongside other then-useful-now-WTF

data like a table of haversines and the physical properties of whale oil).

Sources of error for this instrument will be temperature effects from things

other than the ambient air: radiative heating from the sun or other

surroundings, or direct impingement of precipitation, for instance.

You've probably seen the louvred enclosures at an airport (or, as my brother

pointed out, at the end of the coincidentally-named movie Heat) that are used

to mitigate these effects while allowing air more-or-less to freely circulate.

I learned from the

wikipedia article

that these are called Stevenson screens and that their namesake inventor was

the father of Robert Lewis of the name, author of Treasure Island (!)

To conclude with one more interesting factoid from the wikipedia article:

One of the most precise types of wet-dry bulb psychrometer was invented in

the late 19th century by Adolph Richard Aßmann (1845–1918);

in English-language references the device is usually spelled

"Assmann psychrometer."

Which, like, heh.