I touched briefly on

Stevenson screens

in my

post on hygrometry,

mostly with regard to how cool it is that their namesake was the father of the

famed author.

I'd never built one myself, and never planned on doing until I get around to

building a full-on weatherstation like I will, uh, one of these days.

Then I realized: my girlfriend has a cheap wireless indoor/outdoor thermometer,

and the remote sensor can be a bit, uh, touchy:

Things like this are why we have 3D printers, so I decided to see what might be

publicly available as far as enclosure designs and run one off real quick.

It turns out, Thingiverse has

many options;

I picked

this one

somewhat arbitrarily.

This was a pretty cool model and brought me a little farther into the mindset

of 3D printing than I've been in the past.

I know there are some pretty radical things you can do once you get there

—

printing individual screw threads or a ball in a cage or an entire planetary

gearset in situ

—

but so far I've always treated it as just another traditional

process, proceding from a drawing and using exact dimensions with known

tolerances etc.

This was a different experience:

since I didn't really have any specific dimensions to match, I just scaled it

with the dumb slider in my slicing software and ran test prints until it was

about the right size to accomodate the sensor.

Also, the height of the whole assembly isn't fixed, instead you can print as

many of the annular section as you want to make it as tall as you want.

I did that until it looked reasonable, drove a self-drilling plastic screw

into the bulkhead to mount the sensor, found some all-thread and acorn nuts to

tie it all together and called it good.

At the end of the day, it was pretty fun building something so

fast-and-(literally-) loose, the sensor works much better, and I think it looks

altogether quite professional hanging there on the back fence.

My girlfriend teaches at a local college which has what they call an

"innovation and creativity center."

This is like a hackerspace for college students: they have a small laser

cutter, a bank of FDM machines, the standard stuff.

Its purpose is to give students access to resources for product design, rapid

fabrication, and other resources that students might employ throughout their

studies.

When COVID hit and they sent most of the students home, a small group of

faculty and remaining student workers started turning that equipment to

produce PPE for local hospitals and other communities in need.

So now they're making face shields, with a throughput of a few hundred units

a week.

They're making a couple different models from the many that exist now (the

fire department has stated a preference for one model, the hospitals like a

different one) but which are of the same general construction.

This consists of an FDM

or resin-cast frame, which holds an elastic piece in back for securement and

a piece of transparent PET sheet that comprises the shield.

The latter piece is laser-cut both for general shape and for holes to mate the

mounting studs projecting from the frame.

One problem they were having is that the PET sheet they've sourced comes

on giant rolls, and the material needs to be rough-cut down to fit on the

16x12" bed of the laser cutter.

The rolls are 48" wide, so this is easily enough cut down to either dimension,

but the difficulty comes in making a transverse cut across 48" of material

that's both reasonably square and also close to the 10" dimension required by

the design.

Some slop is forgivable, since each shield is cut entirely from the interior

of a piece and none of the rough cuts forms a finished edge.

But it was still proving awkward and cumbersome to measure and square this by

hand while managing the not-insignificant bulk of the roll itself.

This had become a bottleneck in their production process, so I decided

to build a fixture to help.

Design

Design requirements were pretty straightforward,

the fixture needed to provide three things:

- Some means of retaining the spool and allowing it to unreel in slightly more

elegant fashion than just flopping around on the work surface.

If this can help prevent its getting scratched, so much the better.

- Some form of stop, square to the axial dimension of the reel and against

which the working end of the material can be abutted and made fast.

- Some sort of guide, rigidly fixed at the desired distance of ten inches

from the stop, along which a cutting tool may be worked.

While this allowed a lot of flexibility in implementation, a challenge was the

timing.

This was late March, when Amazon was still quoting lead times of 4-6

weeks on "nonessential" items, hardware and home improvement stores were

basically closed and I myself was trying not to leave the house.

Here's what I made do with parts (mostly) on hand:

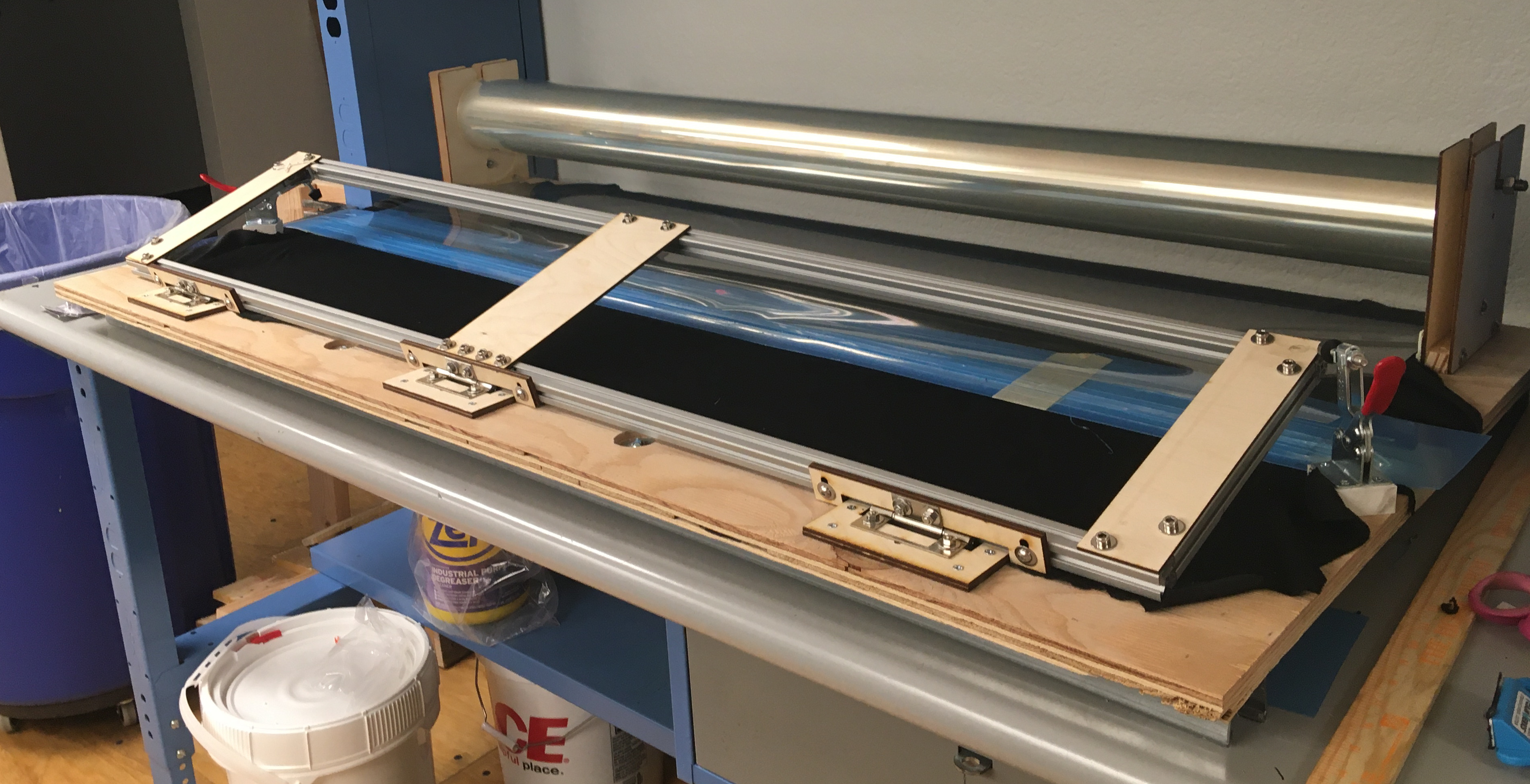

Assembly

The base is cut from some 3/4" subfloor plywood I had lying around.

This was plenty rigid but a little more warped than was reasonable for the

application, so I counterbored from the top and tied into a couple

lengths of steel strut-channel, which got it straightened enough.

With the limited materials I had to work with, this construction is going to

be a bit rough.

The reel is stood-off on plywood that the innovation center was kind enough to

laser for me, sandwiching some scrap 1x1 for rigidity and tie-in to the base.

This plywood is slotted to accommodate a length

of 3/8" all-thread, on which the ID of the spool sits.

The cutting guide is formed by the T-slot aluminum frame you see swung up

toward the image foreground.

This is corner-braced internally but also tied to more plates of laser-cut

plywood you see up top.

Edge-to-edge the frame is 10" wide,

and serves to measure this dimension in the direction toward the spool from

the plywood seen screwed into the base, to which the hinges are affixed

and which serves as the material stop.

When the frame swings down, it then defines a transverse line 10" from the

stop.

It can be toggle-clamped to hold the material in place, allowing the

operator both hands free to manage the cutting tool.

Lessons learned

Altogether this was a very edifying experience, for a couple of different

reasons.

From a systems perspective, this was a great object lesson in limiting

features to scope of project.

The engineer in me looks at requirement (1) above and

immediately starts picturing endcaps that mate the ID of the spool and ride

on sleeve bearings about the axial shaft such that the spool is balanced

around its CoG and spins freely and etc. etc.

That part of me is absolutely horrified at the thought of the spool just

rough-riding over a threaded rod like a roll of toilet paper.

Yet, it turns out, that works just fine.

Any attempt to build a more elaborate mechinism would have taken longer to

design and fabricate, imperiled ourselves of a re-roll if something didn't fit

or otherwise work, and been more likely to fail "in the field."

Similarly, I spent a lot of time thinking about requirement (3) and whether it

would be easiest to build a hot-wire cutter versus a straight, hook, or rotary

blade, what type of guide would best support same, what kind of clearance or

cut-out might be required to accomodate the tool in the bed, etc. etc. before

shelving all of that and just building a straight-edge.

I figured that, if a captive tool were that important, I'd hear about it.

In point of fact, the operators have made do with a manual knife just fine;

the straight-edge was all that was required.

There's a lot of talk in engineering circles about the perils of

overengineering,

YAGNI,

project scope, etc.

For all that talk, actually being able to define and hit targets is still

largely a matter of good judgement and experience and something even seasoned

engineers often fail at.

Being able to take something from concept to delivery and see that it

succesfully meets a need is a rare pleasure and one that keeps me in these

fields.

From a personal perspective, it was also very gratifying to be able to execute

with the limited parts and supplies I had on hand.

For years (at least when it comes to small parts like fasteners and toggle

clamps), my policy has been to buy 25-100% more than I need for the current

project "in case I need 'em for something else later."

This doesn't always feel like the right thing to do, what with the additional

clutter it brings and the alternative convenience of modern supply chains.

Most of my personal projects spend a long time in what we'll call the

"concept/pre-procurement phase."

Being forced by circumstance out of that and directly into execution with just

the stock I'd accumulated "in case I need it" was, again, a very gratifying

and singular experience.

Notes